Hi, all!

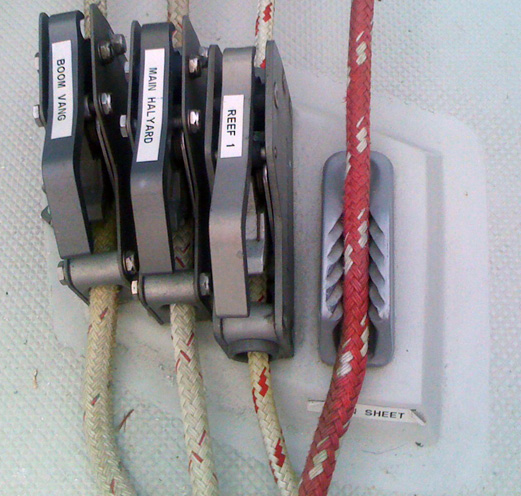

Anybody have info on the pad where the rope clutches are installed? Since the original clutches are NOT through-bolted, I'm wondering if that area was originally reinforced with solid epoxy, or? How is the original hardware secured? I mean - I know there isn't much vertical load (pulling up from the deck), but...

[B]

Here's why I'm asking: [/B]We are in the middle of upgrading our dodger setup. One challenge that came up was the forward-opening original Garhauer rope clutches needing a lot of forward motion in order to open completely - thus requiring the old dodger to be so wide/boxy up-front.

So, we thought about cutting the handles/levers down to shorten them, but then I realized, "Wait a second - I much prefer Lewmar's D2 "reverse" opening clutches anyway!" (I can't tell you how many times I've seen guys accidentally release a clutch by snagging it with the mainsheet, etc...)

So - we are going to upgrade to forward-facing Lewmar D2s, leaving the question: how to mount? To I clutter my interior with through-bolts? Or, do I cut out core, refill with 404/epoxy and bed nuts? Or....????

Thanks!

__________________

Steve Ramsey - Puget Sound

S/V Manonash - '96 C36 mkII (#1586) - M35B

my understanding is that there is an aluminum backing plate that the bolts are tapped into, but I don't have direct knowledge of that.

Gary and Cathy Price

1997 C36 Mk II Tall Rig/Wing Keel Imagine...

Hull # 1617

Worton Creek, Md.

Northern Chesapeake Bay

The deck laminate and reinforcing schedule Word doc that was posted not too long ago shows those areas have a 3/8" aluminum plate in them.

hi bud -

Thanks for the point in the right direction, but after doing about 10-12 keyword searches in the forums, I can't find the word doc you are referring to... Can you post the link, please?

thanks!

__________________

Steve Ramsey - Puget Sound

S/V Manonash - '96 C36 mkII (#1586) - M35B

Steve, it was posted in the forum a while ago, I D/L'd it and kept a copy, which I have attached.

My bad. I converted the doc into a pdf and posted it in the Technical - Reference library...alas, I pdf'd it in a way that required a password to open. I have corrected this, and the document is now permanently on file and available in the C36IA Technical - Reference section.

Larry Brandt

S/V High Flight #2109

Pacific Northwest, PDX-based

2002 C-36 mkII SR/FK M35B

I just added a pair of rope clutches to the stbd side of my '94 C36. Mine had aluminum. I had to drill and tap new holes for mounting. It all went well, except I drilled a little too deep in one of them and the drill bit entered the cabin ceiling. But that was easily patched with a little white sealant.

Capt. Sam Murphy

1994 Catalina 36, Hull 1327

Shoal draft, two cabin model.

Panama City, Florida

Hmm, Steve, you said the original clutches were fastened by screws tapped into the aluminium plate; was that true for the winches, too? My '84 has winches and clutches through-bolted, with nuts inside the cabin, but in the location of the plates. That's how I'd think it would be strongest; I wonder now whether it's an original installation. I was pretty sure I was using the original winches.

Either way, wouldn't it be better to through-bolt those new clutches?

Nick Tonkin

*Former* Website Administrator, C36/375IA

*Former* owner, C36 tr/fk #255, Santa Barbara, CA

CI (is that the name you prefer?)

Since the force vector acting on those clutches is parallel to and very close to the cabin top, having them through bolted is not really necessary.

The cabin-top winch has the same load, but it is applied much higher off the cabin surface and therefore has a much greater 'moment arm' trying to rip it off its mounting. Through-bolting there is a better idea.

Duane Ising - Past Commodore (2011-2012)

s/v Diva Di

1999 Catalina 36 Hull #1777

Std rig; wing keel, M35B, Delta (45#)

Punta Gorda, FL

http://www.sailblogs.com/member/diva-di/

CI,

Your MkI does not have imbedded aluminum backing plates. The winches and rope clutches are thru-bolted. I'm not sure when the change in the design took place.

Tom Sokoloski

C36/375IA Past Commodore

Noank, CT

Thanks for the help and links to the docs, guys...

I was originally thinking of installing a triple-clutch (which would have required tapping new screws, etc...). However, that would have made the side-loading angle a bit more than I was comfortable with - so, I'll be adding singles side-by-side instead. The good news is that Lewmar's D2 has the same 2 11/16 mounting pattern, so I can use the same holes!

CI - No, the winches are not through-bolted on my mkII. But, with the overall depth of that area and the 3/8" plate, I can't imagine it would ever need to be. ;^>

Now, off to recover from falling down the companionway last night (first time in my life, ever...) No big damage, just a bruised knee and ego... ;^>

__________________

Steve Ramsey - Puget Sound

S/V Manonash - '96 C36 mkII (#1586) - M35B

Well, in light of Tom's info that the Mk 1s do not have aluminum plates in the cabin top, then through bolting for the rope clutches does make sense.

Duane Ising - Past Commodore (2011-2012)

s/v Diva Di

1999 Catalina 36 Hull #1777

Std rig; wing keel, M35B, Delta (45#)

Punta Gorda, FL

http://www.sailblogs.com/member/diva-di/

Tom, Thanks for that info. I saw how you used backing plates when you moved your winches and I figured it was because you moved off the (non-existent) plates. My gear is through-bolted but with just washers and cap nuts. You chose to install plates just for more beef?

- nick [ It's Nick :-) ]

Nick Tonkin

*Former* Website Administrator, C36/375IA

*Former* owner, C36 tr/fk #255, Santa Barbara, CA

Nick,

Yes, that's correct. When I bought the boat (it was 3 yrs old at the time) there were a few stress cracks around some of the fender washers already there. When I moved the winches, I added 1/4" aluminum backing plates. No more stress cracks after that.

Tom Sokoloski

C36/375IA Past Commodore

Noank, CT

Thanks Tom. A pair of cam cleats to control the traveler from the cockpit is first on my list of deck hardware upgrades, thanks to your blog :)

- nick

Nick Tonkin

*Former* Website Administrator, C36/375IA

*Former* owner, C36 tr/fk #255, Santa Barbara, CA

Nick - I just moved my cam cleats back, off the traveler, onto the cabin top (leading the line between the winch and the portlight. One tip: I ended up getting Harken's angled riser to go under the cleat, getting up up off the cabin a bit (1/2") making it a bit easier to cleat/release as well...

Good luck!

__________________

Steve Ramsey - Puget Sound

S/V Manonash - '96 C36 mkII (#1586) - M35B

What we have are simple bullet fairleads forward near the dodger and then the line runs flat to the cam cleats at the edge of the cabintop. Better yet, get swiveling cam cleats, you'll appreciate the better line handling when underway.

Stu Jackson, C34IA Secretary, C34 #224, 1986, SR/FK, M25 engine, Rocna 10 (22#)

Steve and Stu,

These changes are interesting...could you post pictures for us to see?

Stephen Kruse

Kruse Control #1428

1995 C-36 MKII SR/WK

Lake Lanier, Ga.

Steve and Stu, I have a C36 Mk 1 and I suppose the gear is different throughout to the Mk 2 and the C34 . . . The cam cleats on the traveler on my boat are not removable; the jaws are screwed onto an extension of the base plate. Wondering if yours were completely removable or did you have to cut/grind to get them off the traveler?

I saw that on the pics of Tom Soko's boat he reversed the lay of the lines through the traveler blocks and routed them forward of the traveler then back under it. Did you do the same?

Also saw that he routed the lines through a block fastened to the side of the companionway hatch cover; how to fasten an eye to the side of that cover? I was a bit surprised that he chose to fasten the eyes there since it's just 3/16 or 1/4 glass as far as I can tell.

thanks

Nick

Nick Tonkin

*Former* Website Administrator, C36/375IA

*Former* owner, C36 tr/fk #255, Santa Barbara, CA

Nick,

That's correct. The sides of the companionway hood are not very thick. I'd guess that 3/16" is about right. I used self-tapping SS screws, thinking that on the first "less than perfect" gybe they would get pulled out, and I would have to take off the hood and install machine screws with fender washers. After 3-4 years, and many less-than-perfect gybes, the screws were holding fine when I sold the boat.

Tom Sokoloski

C36/375IA Past Commodore

Noank, CT

Reply #4 in this earlier Winch/Clutch alignment topic: [url]http://www.c36ia.com/forums/showthread.php?t=1498[/url]

Stu Jackson, C34IA Secretary, C34 #224, 1986, SR/FK, M25 engine, Rocna 10 (22#)