Here is what I did to to avoid overheating and requiring burping the fresh water system after it is flushed and new antifreeze is added.

Here is what I did to to avoid overheating and requiring burping the fresh water system after it is flushed and new antifreeze is added.

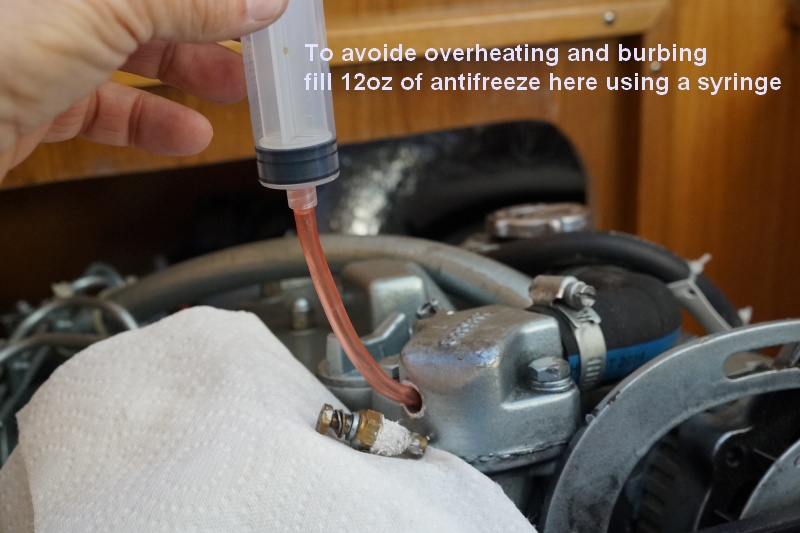

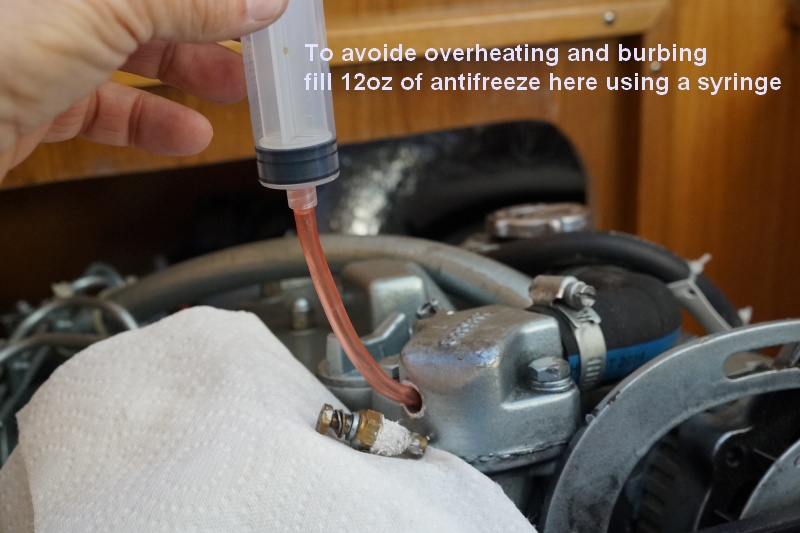

After as much fluid has been added through the filler cap that is possible, install the filler cap and add about 16 oz of fluid in the reservoir then remove the water temperature sending unit at the top of the engine and use a syringe with a flexible hose to fill about 12 oz of fluid through this opening until fluid starts to come back out. Then reinstall the sending unit.

The reason for over heating is that after the coolant is added the thermostat prevents fluid from filling the fresh water pump chamber. When engine runs no fluid is circulated so the water temperature continues to rise. By filling the top of the engine through the water temperature sending unit opening, the fresh water pump fills with fluid and is able to circulate the water.

View my previous comment on flushing the fresh water system here

.

Haro,

Great idea! One word of caution. The temp sender should not have any teflon tape on it. There should be a good metal-to-metal connection between the sender and the thermostat housing, otherwise the sender will not work properly. Just a thought.

Tom Sokoloski

C36/375IA Past Commodore

Noank, CT

A couple points....

1)

Although nto recommended, PTFE tape usually does not insulate/isolate the threads. It fills the tiny, continuous, gap that forms between the peak and valley of the thread. The flimsy tape typically is not robust enough to withstand the metal-to-metal shear when the body of the threads make contact and are tightened (tapered threads.) THAT SAID, if you want to assure electrical contact and ease of removal, wrap only the very end of the male thread which will "dam up" the leak passageway, and use some copper content NeverSeize (auto parts store or online) on the threads for electrical continuity and corrosion/galling prevention.

2)

Oftentimes, maintaining a bond between the T cap and engine block is an issue, and the resistance increases and can appear to be a faulty temp gauge -- you can remove the cap, clean the bolt threads very well, and reinstall with the copper never seize - which helps maintain continuity, virtually reduce corrosion and galling of the threads, and makes removal very easy later on.

3)

Also, a grounding strap can be used on the sender -- like a solid stainless mini hose clamp, fitted with a ring terminal and a bonding wire to ground. A strap like this works well

www.ultimategarage.com

http://www.ultimategarage.com/shop/images/miniclamps.jpg

4)

The burp airlock can probably also be avoided by bleeding the Tstat cap. The thermostat has holes in its flange to bypass some flow to prevent hot spots in the block while the coolant warms up before the Tstat opens. Remove the T cap. drill and tap for a 1/8"-17 NPT thread, and install a petcock. Then release air while filling with coolant, rev/fill until coolant spews out the petcock.

Ken Kloeber

"Positive Impact"

Lake Norman NC

1984 C30 #3573

TRBSFK M-25

I neglected to mention that the white stuff is pipe thread paste.

It makes it leak proof and makes it possible to remove later easily. It remains soft.

Sail La Vie 1999 Catalina 36 MKII, M35B-17031, Coyote Point, San Mateo, CA

About Sail La Vie