Hi all, I've got a new to me 1993. My first major project is to tackle the rudder tube.

I've been reading articles on this site and they are very helpful. Thank you.

I think I have an idea of what I'm getting into - but I'd appreciate and tips or suggestions.

Here is my plan:

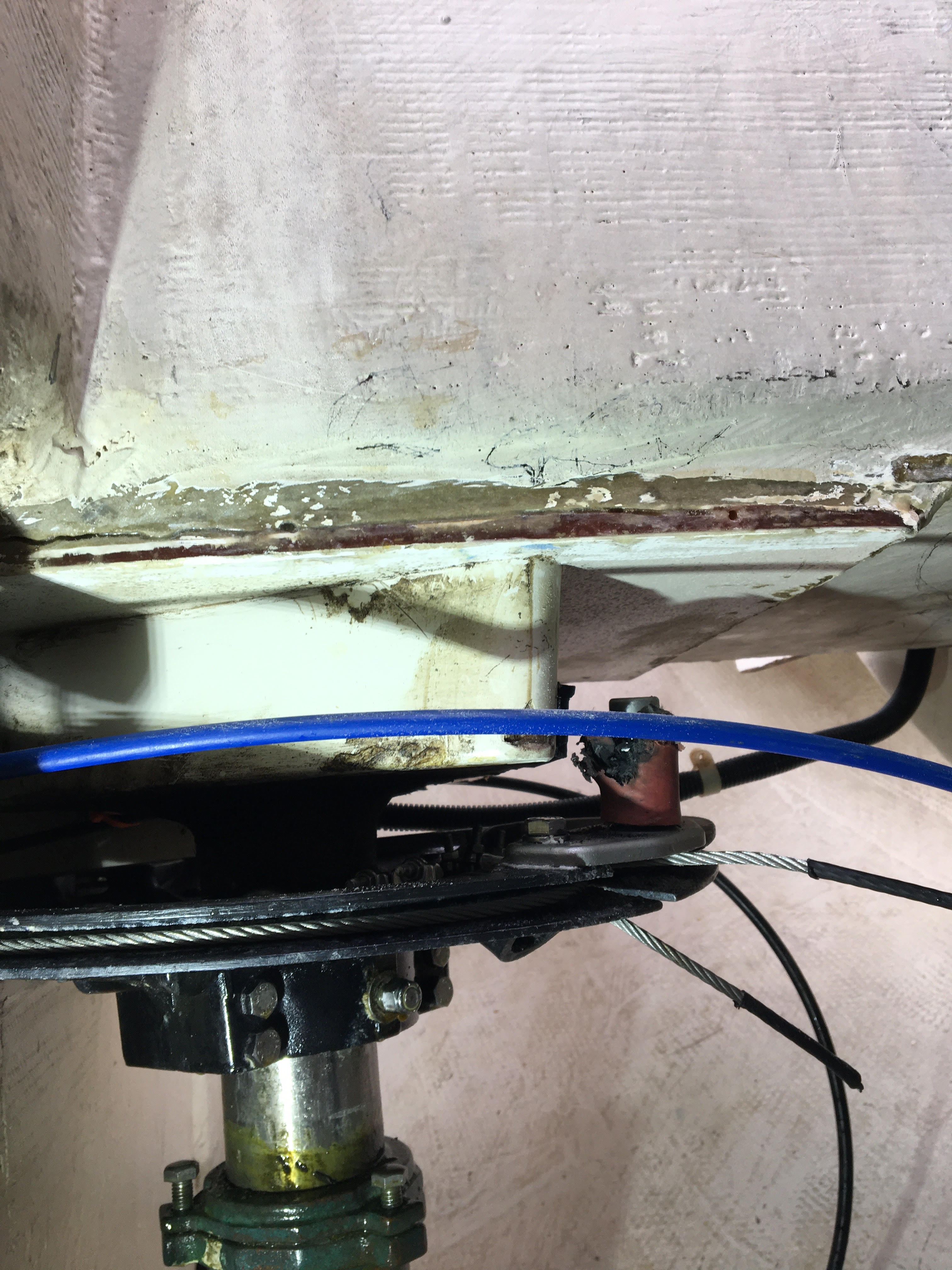

1 - Epoxy the crack where upper rudder box is delaminating from the deck - like the Rudder Bearing Repair posted by Perseid. Note photo attached is after 1st epoxy and clamping, but before finishing.

2 - Remove quadrant, remove rudder - boat is on the hard for the winter and I have dug a hole.

3 - Epoxy lower portion of stuffing box back into lower rudder tube - see photo

4 - Inject Epoxy & graphite into shaft to reduce lateral play - per Rudder Tube Resin PDF and CD kit.

5 - fit new top bearing to reduce vertical play.

Specific questions:

Other than penetrating oil and patience, any suggestions for removing the quadrant? It's quite frozen.

How much vertical play is "normal"? I have about 7mm clear between the hull and the rudder washer - see photo

Thanks, Ken

in addition to your planned work - I recommend replacing the push-pull cables - just cause your in there anyway.

I had on heck of a time getting the quadrant off Mahalo. I broke 1 bolt and had to grind the head off another. I have an 83 so the SS bolts were screwed tight to the aluminum for more than 35 years - plenty of time to corrode in lock everything tight (I used penitrating oil, heat, biggest electric impact wrench i could find). Going back in I replaced the bolts tapped into aluminum by drilling out the threads and using new stainless thru bolts, washers and lock nuts.

going back in with the rudder, be sure and NOT have the stuffing or cap on the post. Get the rudder post exposed, stop and put the cap on the shaft -- otherwise you will most likely push the stuffing box off the tube.

Take a look under you "tiller head" for a plastic thrust washer - this might be what is causing some of your excessive rudder drop.

Les

Good luck!

Les & Trish Troyer

Mahalo

Everett, WA

1983 C-36 Hull #0094

C-36 MK 1 Technical Editor.

Commodore

Thanks Les, I really appreciate your comments.

It took me a month and lots of patience (and lots of penetrating oil!) but I finally got the quadrant off. I twisted and almost broke 1 ss bolt, but eventually I coaxed it out.

I think you are right about the washer under the "rudder head". Mine is cracked and has a sharp edge. The rudder tube as well as the underside of the "rudder head" have beed ground down. There is now a 1/4" deep groove worn into the top of the rudder tube and the entire assembly sits low - thus my excess drop.