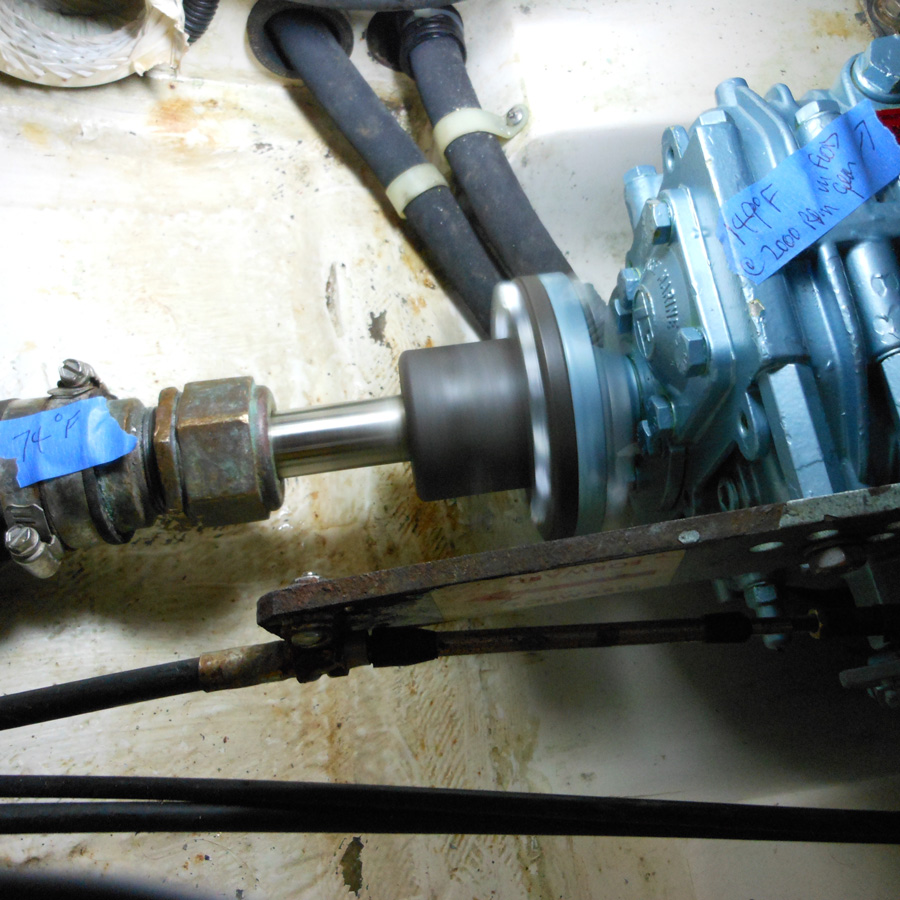

Got an infrared thermometer recently (they're cheap nowadays) and used it to find out how my new Teflon packing and my newly overhauled transmission were running. The packing was adjusted to almost no drips...maybe one drip every 5minutes. After running at 2000 rpm in forward gear in the slip for almost 2 hours, the temps stabilized as noted below:

The temp of the shaft log was measured on one of the flats of the packing nut. The temp of the transmission was taken on the case immediately beside the filler nut.

—

Larry Brandt

S/V High Flight #2109

Pacific Northwest, PDX-based

2002 C-36 mkII SR/FK M35B

Larry, I did the same thing, the infrared temp gauge is so handy, check the water temp before you jump in, see how hot the roast is, the possibilities are endless. You can never have too many tools I guess.

Our trans temp is about the same as yours. Under load at 2400 rpm our packing box runs in the high 95-100 degree area in summer water temps of 75 or better degrees. Cooler in spring or fall.

I put Gore GFO in it this year, I had some other black stuff from Pacific Western last year and it ran hot, around 130-140 degrees which they said was OK when I emailed them about it. Might have been but I didn't like it that hot.

I only put 2 rounds of packing in this year, if I put 3 in I only have about 1.5 - 2 threads of engagement on the spud nut and that's not enough strength for the lock nut IMHO. Even with 2 rounds of packing I can control the drip easily. I like to see it drip about 6 times a minute. I have a little tray in there with a tube that runs the water into the main bilge so water ingress doesn't cause any issue. So far very pleased with the GFO.

Have not yet written it up but I connected a temp sensor directly to my stuffing box for the entire 6.5 month season and 1100nm. The one BIG thing I discovered is that these temps are NOT static. I suspected as much but dd not realize how randomly they would spike up..

My guess is that as you move water gets sucked out of the shaft log and is replaced by some air bubbles or when you hit reverse some air gets trapped up in there? This is probably why PSS had soo many issues with entrapped air and the need to burp more often than just upon launch and why they added a vent to ALL PSS seals. My C-36 was a boat that needed chronic burping before vented seals.

With the box having no drips I could start out running at 75-90 degrees for 20-30 minutes then watch it gradually climb to about 130-140F. Next thing you know the temp is over 200F. I repeated this over and over and over. The packing was adjusted VERY, VERY slowly and broken in very, very slowly and there were three rings. The rings were "bench packed" to be sure it was absolutely perfect.. The bottom line is that SOME dripping was the only way to prevent the temp spikes.

If I had just hit it once or twice with a pyrometer I would have seen good results and not thought anything of it. When you have a digital gauge in the cockpit staring you in the face for 1100 nm you tend to see a lot more.

I finally got it down to about 1 drop every 2-3 minutes and that kept it from "spiking" after a while. No drips=spikes to well over 200f. I once saw it at 222F confirmed with my Raytek Pyrometer.

To eliminate false readings or screwy test parameters this was new Gore packing, a brand new Buck Algonquin box and brand new 1" AQ22 shaft. Boat gets hauled in a few days and I will yank the shaft and inspect, as it got damn hot a number of times when experimenting with no-drips..

-Maine Sail

https://www.marinehowto.com/